Industrial Engine Rebuilding Service

Engines in industrial premises are subjected to a lot of wear and tear. Proper maintenance can enhance the life cycle of the engines and the best way to do this is through industrial engine rebuilding services. Outsourcing the service of these professionals will improve the longevity of your industrial engines and this will make it work better than before. The results of an engine rebuild service is a good as new as professionals always pay detailed attention when working on these devices.

If you want to enhance the efficiency of your services and are looking to become more competitive in the marketplace, you need to ensure the engines of your machines are of top quality. Engine rebuilding services offer maintenance in parts such as Dresser-Rand Genuine and Arrow Parts efficiently and at competitive prices. You’ll get quality replacement parts to fit your industrial engine requirements.

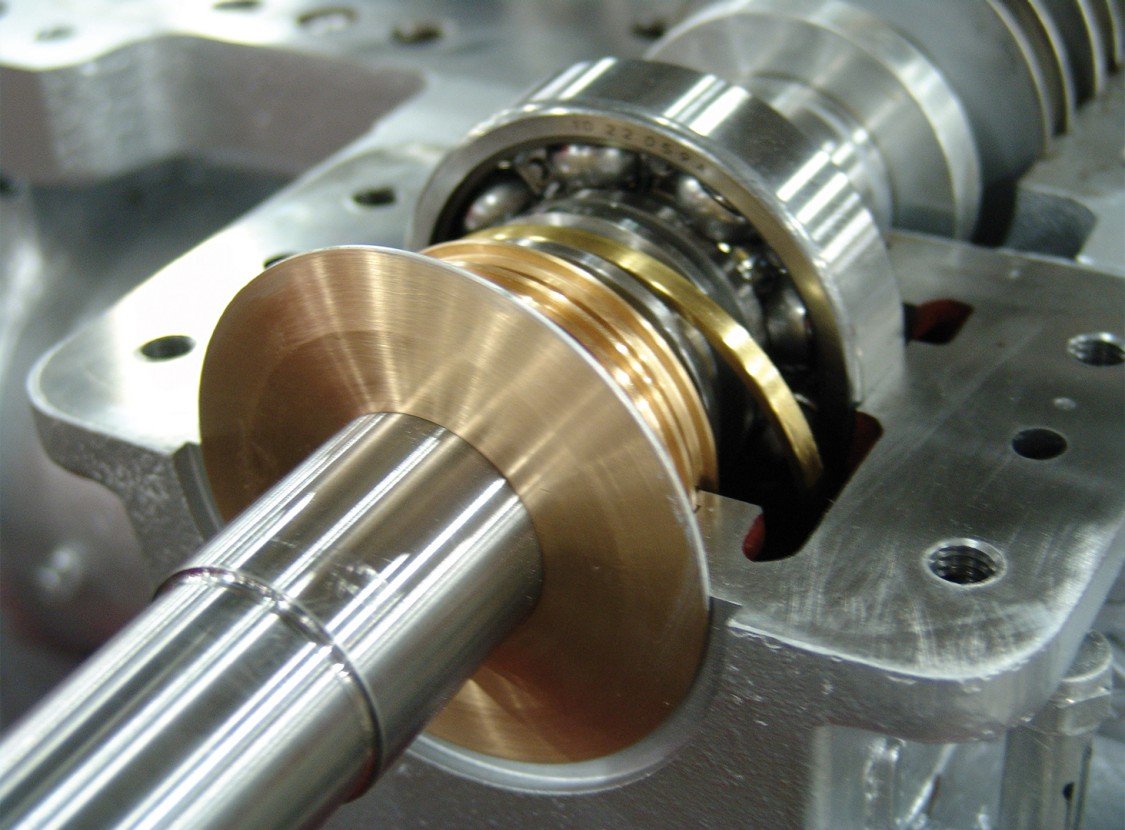

Professional service providers are there to meet the demands of an altering business environment. We have committed repair resources that are particular designed for engines and affiliated essential services. Factory-trained technicians particularize in certain components to offer dependable and fast rebuilds. The assembles are disassembled during the engine rebuild process. The large components and engine blocks are cleaned in different cleaning facilities while are small ones are washed in agitating chemical vessels.

If you realize that there is excessive oil consumption, excessive oil clearances, or a loss of compression, it's probably time you look for engine rebuilding services. A compression loss could be because your engine lacks power or your engine has a regular misfire. An engine rebuilt service s much cheaper than buying a new one and much more cost-effective in the long end than acquiring a second-hand one as it is not possible to have mechanical problems.

All the parts are checked during an engine rebuilding process and new components are brought in to replace the spoiled ones. Second-hand engines may have problems you may not be aware of and this may affect the performance of the machine in the long run. Purchasing a new engine means you’ll have to throw your current one. This leads to engine components consuming space in your organization and other unpleasant fluids draining and contaminating groundwater reserves.

Variance in engine heads makes it hard to outline the process of the operation. Engine heads are built with various design processes. Air or water can be used to coo, the engine heads. One of the most essential parts of the engine rebuilding procedure is machining. Quality machining gives your engine endurance and power. The goal of professionals is to constantly satisfy the wants of their clients. When called upon, they react quickly so that the company’s productivity isn’t affected. The next time you need OEM dresser and compressor parts, don’t think twice to call us. Your industrial engine needs will be in the best hands if you hire an experienced OEM dresser rand compressor parts rebuild service. You can go online to look for some of the best service providers near me so that you make a detailed final selection.